Based on the customer’s enquiry, detailed and specific estimates are made regarding the production aspects and the costs. CIMA definition of Job costing is “It is a form of specific order costing in which costs are attributed to individual jobs”. Thus, each ‘Job’ is treated as a distinct cost unit for which costs are accumulated.

Product Mix:

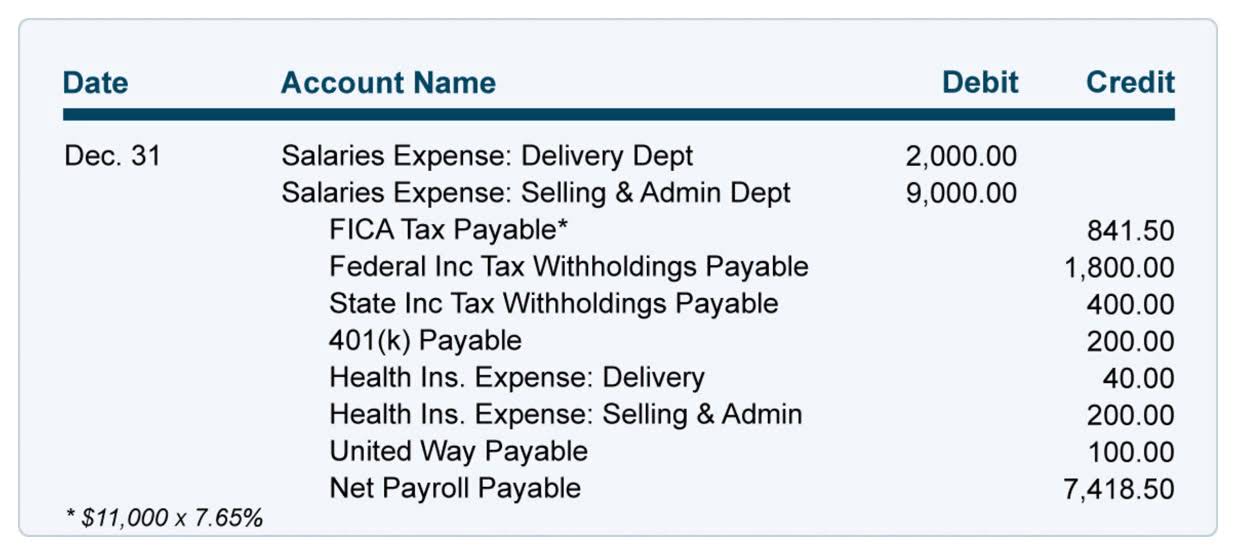

By following these steps, businesses can implement an effective job costing system that allows for accurate cost tracking, informed decision-making, and improved profitability. These include estimated daily expenses necessary to complete a project, such as rent, depreciation, machine running costs, utilities, and more. Due to the complexity of accurately estimating these costs, businesses typically apply a standard overhead fee to QuickBooks Accountant each project. The total cost of a job as indicated by the job cost sheet consists partly of direct cost and partly of costs arrived at by assignment, allocation, apportionment and finally by absorption. Thus it is clear that similar jobs executed during a certain time period are bound to have different units of production.

Features of Job Costing:

- The first quarter of 2022 was a stressful time for commercial construction companies, with labor shortages and high material prices creating delays at jobsites.

- Sling really is the go-to solution for all your scheduling and job costing needs.

- This gives management time to either get costs under control over the remainder of the project, or possibly to approach the customer about a billing increase to cover some or all of the cost overrun.

- Let’s us consider a construction company that specializes in building custom homes.

- We can help you create a job costing system that lets you evaluate the profitability of existing projects and assess whether future projects are worth taking on.

- Job costing forecasts project expenses and helps you price your services to ensure profitability.

But as they’ve been taking on bigger projects, they haven’t been able to understand how each job has impacted their bottom line. The purpose of the estimate is to get an idea of what the job will cost and how profitable it will be. (ii) Certainty of profits in case of increasing prices of labour and material. (v) If material, labour, machinery and expert is provided by the contractee and contractor is to do the work of contract only. In the event of a loss on uncompleted contracts, this should be transferred in full to features of job costing the Profit and Loss Account. There may be three situations in the computation of profit or loss on contracts.

Preparation of Job Cost Sheet:

It’s important to remember that if subcontractors are hired for specialized tasks beyond your company’s expertise, their costs should be included. This ensures that your labor cost calculations are accurate and comprehensive. Before we learn how to calculate job costing, let’s look at one of the tools that aid in job costing, called a costing sheet. A cost accounting system should be so designed that it would be able to provide the necessary information for achieving control of cost and performance. Thus it shows in detail their cost components of the total cost of executing a job which may take the form of either a special order or job or a batch of orders. (ii) It records costs more accurately and facilitates cost control by comparing actual with estimates.

- (ii) Excessive increase in expenses, since contractor is not worried about increasing cost.

- However, two carpenters must work overtime because of an absence on the shop floor.

- Still, due to its cumbersome detailing, the cost sheet loses its importance, and most organizations fail to include all the material, labor, and overhead details in their cost sheet.

- Job costing is possible only in businesses where the production is done as per the customer’s requirement.

- By comparing the total cost incurred with the revenue generated from each job, businesses can identify their most profitable areas and focus on those.

When would job-order costing be used in preference to process costing?

(8) In both the cases quotation is called by the customer before placing the order. (7) In both the cases work commences on the receipt of order from the customer. (k) Work-in-progress may or may not exist at the end of the accounting period. If the customer is satisfied with the quotation, he may place an order which may be accepted by the firm for execution.

Job Costing vs. Process Costing

- Others like those constructing a house or offering a service will also benefit from job costing.

- Whether building custom homes or crafting specialty machines, accurate cost tracking is essential.

- It is a method which determines the cost of specific jobs, which are performed according to the consumer’s specifications.

- A job costing sheet comprises different factors within the business and the culmination of all these factors gives the management clarity on things like budgeting, raw material, etc.

- Manufacturers rely on accurate financial reporting for solid business decisions; job order costing gives them the detailed data they need for success.

These professionals also allocate indirect costs like office rent and utilities to each job. Job order costing helps find mistakes before they become big problems. It makes sure every dollar gets put in the right adjusting entries place for each project. With practical advice and real-world examples, we’ll explore how job order costing can lead to better cost management and enhanced profitability for your business endeavors. Cal Wadsworth Construction uses a combination of BILL Spend & Expense and corporate credit cards to skip manually coding projects on transactions and streamline their reporting.